© Tillypad 2008-2014

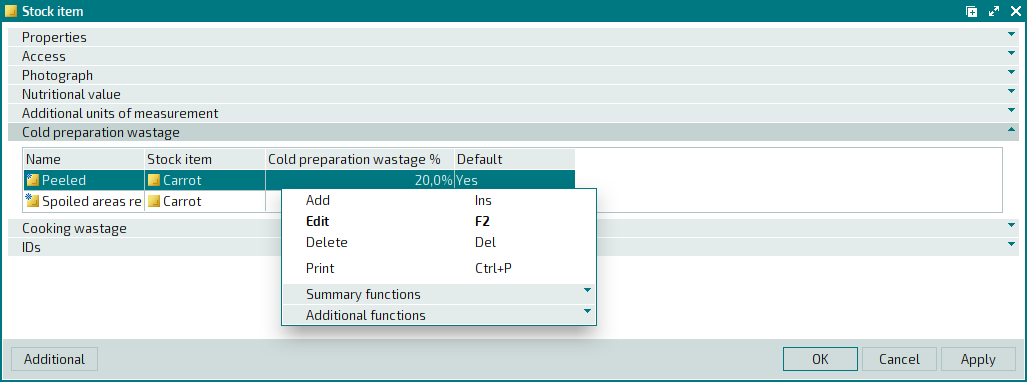

The Cold preparation wastage panel is intended to manage cold processing of stock items. The panel contains a data grid to specify how much of the compound stock item is processed (skinned, cut, gutted, etc.).

Data grid columns:

Name is the name of the cold preparation wastage type.

Cold preparation wastage % denotes the percentage of the stock item quantity modified during cold preparation.

Modification percentage can be positive or negative. Positive value shows what part of the stock item will be lost during cold preparation. Negative value indicates by what percentage the quantity of the stock item will increase.

Default indicates whether this type of cold preparation is set as the default option.

Stock item is the name of the stock item to which the cold preparation type applies.

The specification context menu contains the following commands:

(Ins) – adds a new cold preparation wastage type.

(F2) – edits the selected cold preparation wastage types.

(Del) – deletes the selected cold preparation wastage types.

(Ctrl+P) – generates print layouts.

– menu with the commands to manage the summary functions of the data grid.

– menu with the commands to operate the data grid.

The entry window is used to add a new cold preparation wastage type to a stock item. The and editor windows are used to edit parameters of cold preparation wastage types.

A confirm permanent deletion prompt appears when you delete cold preparation wastage types.

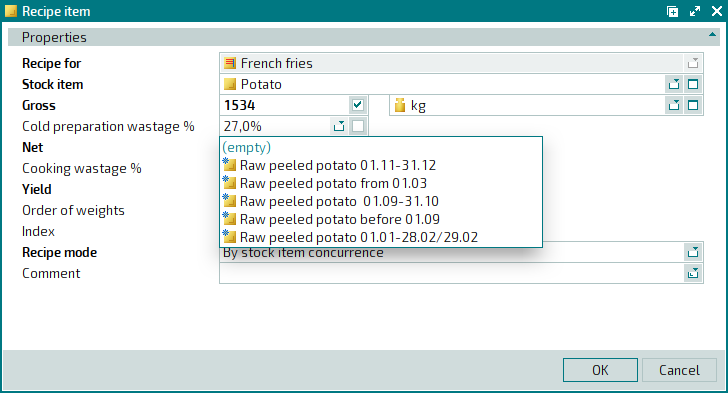

Cold preparation wastage types can be selected from the Cold preparation wastage % drop-down list enabled in other windows.